Fire Alarm systems for Domestic Premises

Domestic fire detection and alarm system standards are outlined in the BS 5839-6:2019, as amended 2020 Code of practice for the design, installation, commissioning and maintenance of fire detection and fire alarm systems for domestic properties.

In this edition there have been some changes to the “Grades” of systems from the previous edition.

The type of domestic premises covered by this British Standard are:

A) designed to accommodate a single family;

B) houses in multiple occupation comprising a number of self‑contained units, each designed to accommodate a single person or family;

C) sheltered housing, including both the dwelling units and the common areas;

D) supported housing.

The recommendations within the standard apply to both new and existing domestic premises with the types of domestic property’s covered include:

– Bungalows,

– Multi-storey houses,

– Individual flats,

– Individual maisonettes,

– Mobile homes,

– Individual sheltered accommodation as well as their common parts,

– Houses in multiple occupation (HMOs),

– Certain NHS housing in the community,

– Mansions,

– Shared houses,

– Houses divided into several self-contained single-family dwelling units.

It also applies to premises used for self-catering holidays if occupied by not more than ten persons, and premises with short-term paying guests in the home of a resident operator with not more than eight guests.

It is limited to premises in which guest accommodation is not located below a ground floor or above a first floor, and in which no storey is greater than 200 m2 in area. For larger premises, the recommendations of BS 5839‑1 apply.

This standard does not to the following property’s:

– Hostels,

– Caravans or boats (other than permanently moored boats used solely as residential premises),

– To the communal parts of blocks of flats or maisonettes.

It does not apply to any premises used for purposes other than as domestic premises (e.g. small shops, factories or similar premises used solely as places of work).

This British Standard breaks the fire alarm and warning systems down into 8 “Grades”.

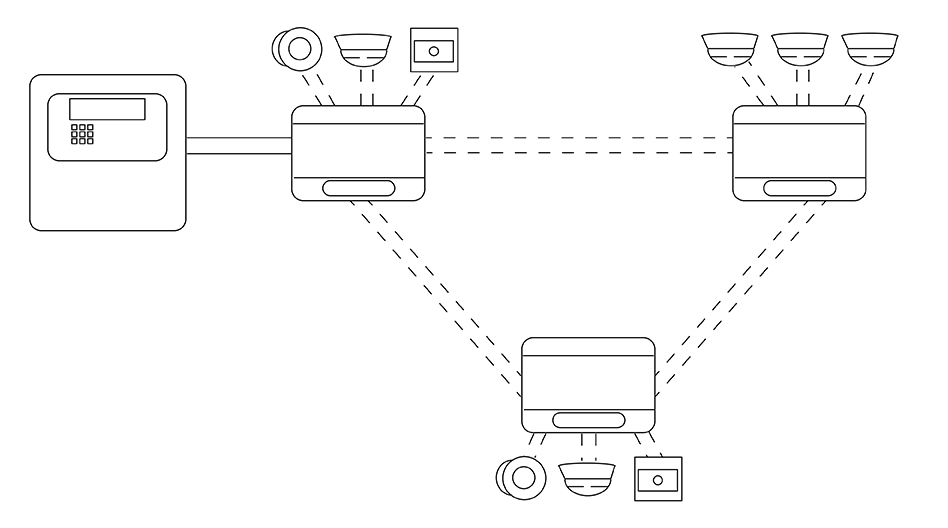

System grade relates to the engineering aspects of the fire detection and fire alarm system. Higher grades of system tend to provide a greater level of control and monitoring of the system, or greater reliability and availability to perform correctly in the event of fire. The grade of system that needs to be installed depends on the nature of the premises, the level of fire risk and the characteristics of the likely occupants.

Grade A

- – This system is designed and installed in the main according to the recommendations of BS 5839‑1:2017, (Code of practice for the design, installation, commissioning and maintenance of fire detection and fire alarm systems for non domestic properties). The detectors, sounders and the central control and indicating equipment with a back-up power supply conform to British Standards BS EN 54-2 and BS EN 54‑4.

Grade B

Grade C

- – A system of fire detectors and alarm sounders (which may be combined in the form of smoke alarms) connected to a common power supply, comprising the normal mains and a standby supply, with central control equipment.

Grade D1

- – A system of one or more mains powered detectors, each with a tamper‑proof standby supply consisting of a battery or batteries

Grade D2

- – A system of one or more mains-powered detectors, each with an integral standby supply consisting of a user‑replaceable battery or batteries.

Grade E

Grade F1

- – A system of one or more battery-powered detectors powered by a tamper‑proof primary battery or batteries

Grade F2

- – A system of one or more battery-powered detectors powered by a user‑replaceable primary battery or batteries.

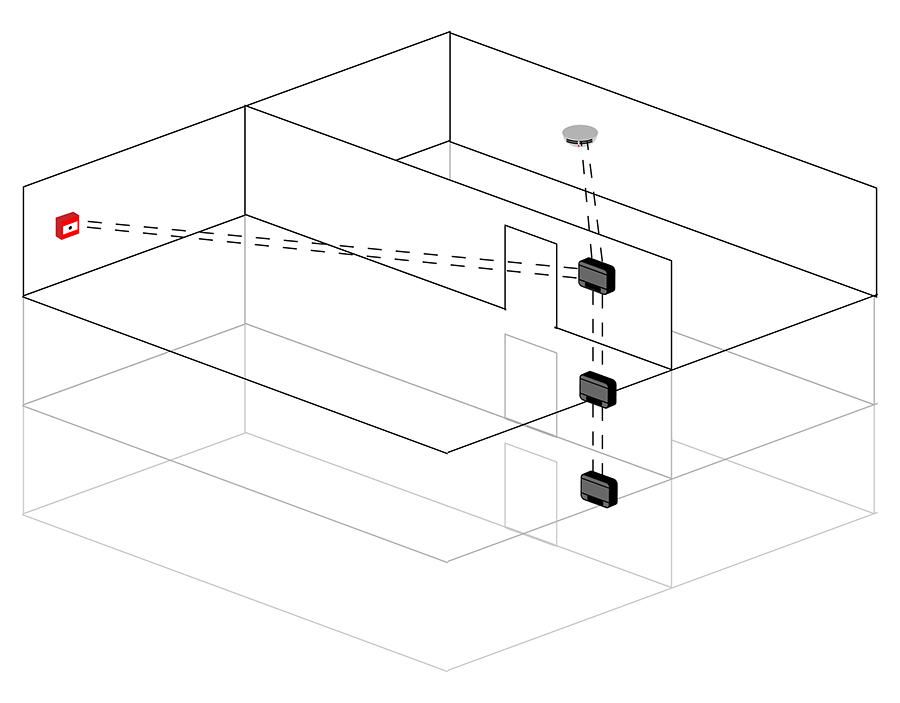

In the case of Grade D and Grade F systems, where more than one smoke or heat alarm is installed, these normally need to be interlinked.

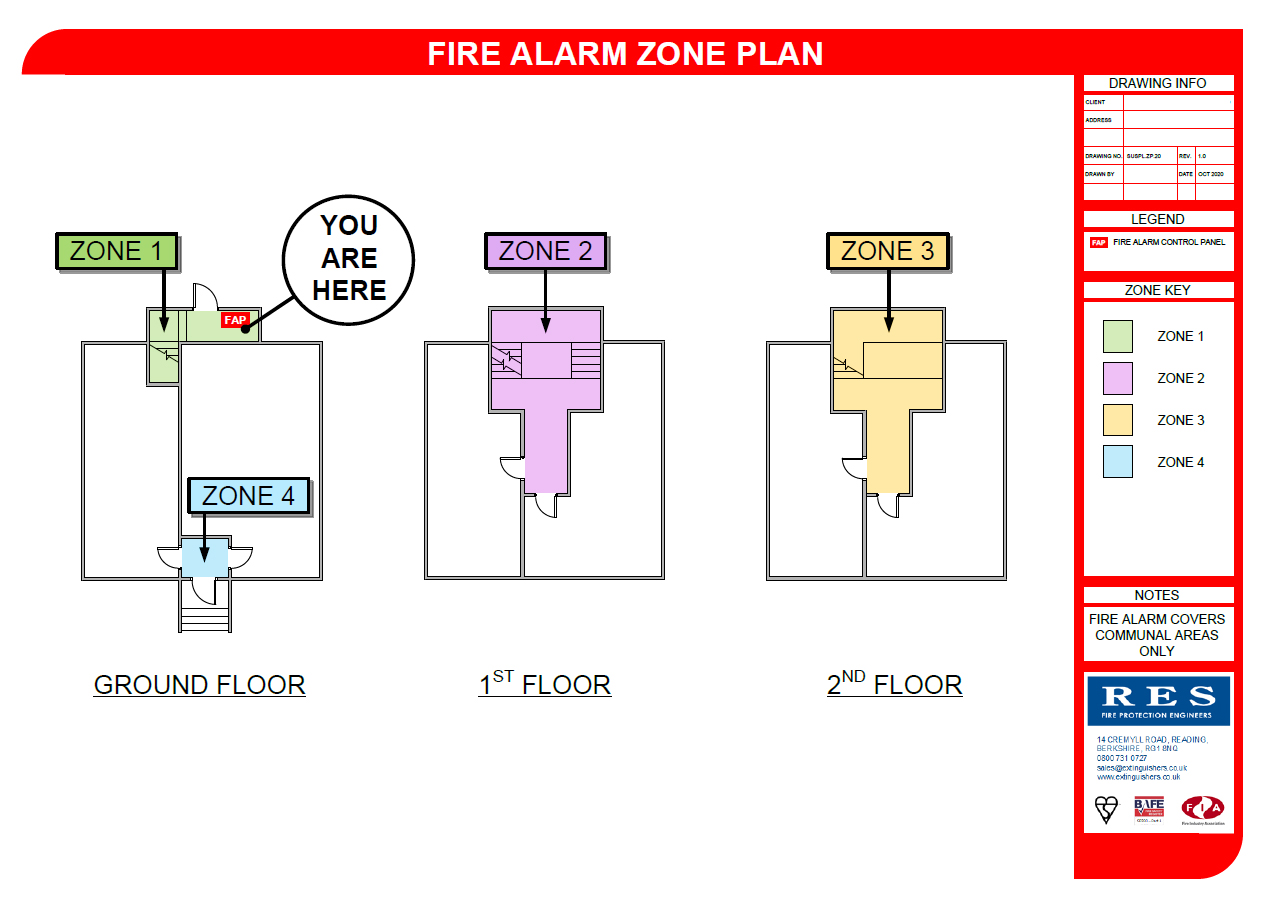

Levels of Protection/Categories of System

There are three categories for domestic fire detection and fire alarm systems these categories outline where the detectors/sounders should be installed and level of protection given, the “LD” indicates that the fire detection and fire alarm system is intended for the protection of life.

All domestic premises need to be provided with an appropriate fire detection and fire alarm system, for full coverage a Category LD1 is installed, such a system gives the earliest practicable warning of fire to occupants, wherever ignition occurs.

However, a good level of protection can normally be obtained from a Category LD2 system, in which detection is only provided at points where the fire risk is high or where combustion products would present a significant hazard to life. A Category LD2 system might, for instance, have detectors only in the circulation areas of premises, the living room and the kitchen; other areas might be left without detector coverage. The areas protected by a Category LD2 system include escape routes, i.e. those areas that would be protected by a Category LD3 system.

A Category LD3 system is intended only to protect circulation areas that would be used as escape routes.

Category LD1

- – A system installed throughout the premises, incorporating detectors in all circulation areas that form part of the escape routes from the premises and in all rooms and areas other than those with negligible sources of ignition, such as toilets, bathrooms and shower rooms.

So detectors/sounders are typically installed in Hallways, Landings, Living Rooms, Kitchens, Bedrooms, Airing cupboards/Meter cupboards etc

Category LD2

- – A system incorporating detectors in all circulation areas that form part of the escape routes from the premises and also in all specified rooms or areas that present a high fire risk to occupants, including any kitchen etc.

So detectors/sounders are typically installed in Hallways, Landings, Kitchens etc

Category LD3

- – A system incorporating detectors in all circulation areas that form part of the escape routes from the premises.

So detectors/sounders are typically installed in Hallways, Landings etc

This article is intended as a summary guide and is not a substitute for the full Code of Practice of BS 5839 Part 6: 2019, A1:2020. More information can be accessed here:

You can buy the full BS 5839-6 online from the BSI Shop

Building Regulations are available for free from gov.uk

;)